Once a material model has been selected and calibrated to the test data, Veryst recommends validating the model by performing a test with a stress state different from any used for calibration. This test can be complex and include inhomogeneous deformation. Such a test ensures that the model can accurately represent the material in load cases other than those encountered during the tests. We recommend performing, when possible, a test that is representative of the stress state the product will experience. Some tests we often recommend are:

- Instrumented ball impact test

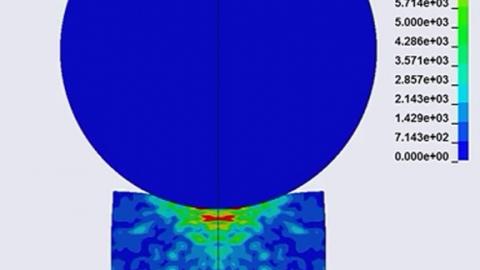

- Dynamic punch test

- Three- or four-point bending

Veryst also designs custom test geometries and fixtures to mimic best the stress state of a particular application or problem. For more information on validation testing, write to us at contact@veryst.com.