Polymers at Elevated Temperatures: Design Risks and Strategies

Free, One-hour Webinar

Exposing plastics and polymers to elevated temperatures can expose products to increased risk of failure. Knowing how to identify the correct material and deploy it in your products requires understanding the structure and analysis of polymers. In this webinar, you will learn how to anticipate, recognize, and mitigate the effects of elevated temperatures on polymers and plastic materials.

Details

Course Instructor

Dr. Scott Grindy is a Lead Engineer at Veryst Engineering. Dr. Grindy’s expertise is in the design of functional polymeric materials through materials chemistry and structure. He has worked extensively with polymeric materials such as soft hydrogels, thermoplastics, photo-curing systems, and biodegradable polymers.

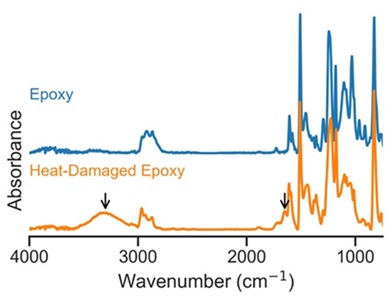

Dr. Grindy has experience using both mechanical characterization such as DMA (dynamic mechanical analysis) and rheology and analytical methods such as FTIR (Fourier-transform infrared spectroscopy), DSC (differential scanning calorimetry), and HPLC (high-performance liquid chromatography) to analyze materials in wide-ranging areas that include drug delivery, implantable biomedical devices, adhesives, and consumer products to understand how material structure and chemistry drives performance.

Prerequisites

This course is intended for mechanical or design engineers who may not have extensive experience with polymer materials.

Learning Objectives

By the end of the webinar, you will have an improved understanding of:

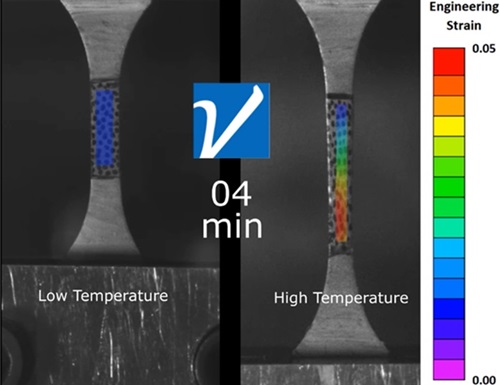

- Why polymers are temperature sensitive

- The attributes of polymer structure that cause improved temperature performance such as crosslinking, crystallinity, and backbone structure

- The glass transition and its implications for product design

- When to anticipate different failure modes like creep, melting, or degradation and how to test and compare materials

Registration

The March 13, 2025 Polymers at Elevated Temperatures: Design Risks and Strategies web-based course is free, but registration is required and class size is limited.

Register at:

If you have any questions, please email us at seminars@veryst.com

Deadline for registration is: Friday, March 7, 2025.

Cancellation Policy

Veryst reserves the right to reject registrations and to cancel a webinar based on class size.

Important Information

* You will receive an email confirmation once you have completed your registration.

* You will receive an email with login information the day before the webinar.