Veryst has extensive experience in designing and developing electromagnetic heating systems, leveraging deep expertise in electromagnetics, heat transfer, and computational modeling. We provide practical recommendations to help clients design more efficient and effective thermal systems across various industries.

Our engineers specialize in modeling and designing high-temperature electrical pass-throughs for CVD reactors, inductively heated catalytic processes, and RF tissue ablation devices. We also incorporate fluid flow, chemical reactions, and material selection into our analysis to optimize system performance.

To discuss your electromagnetic heating application with our team of experts, email us at contact@veryst.com today!

Joule (Resistive) Heating

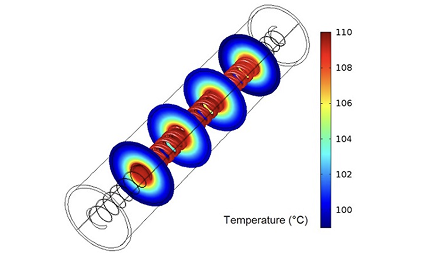

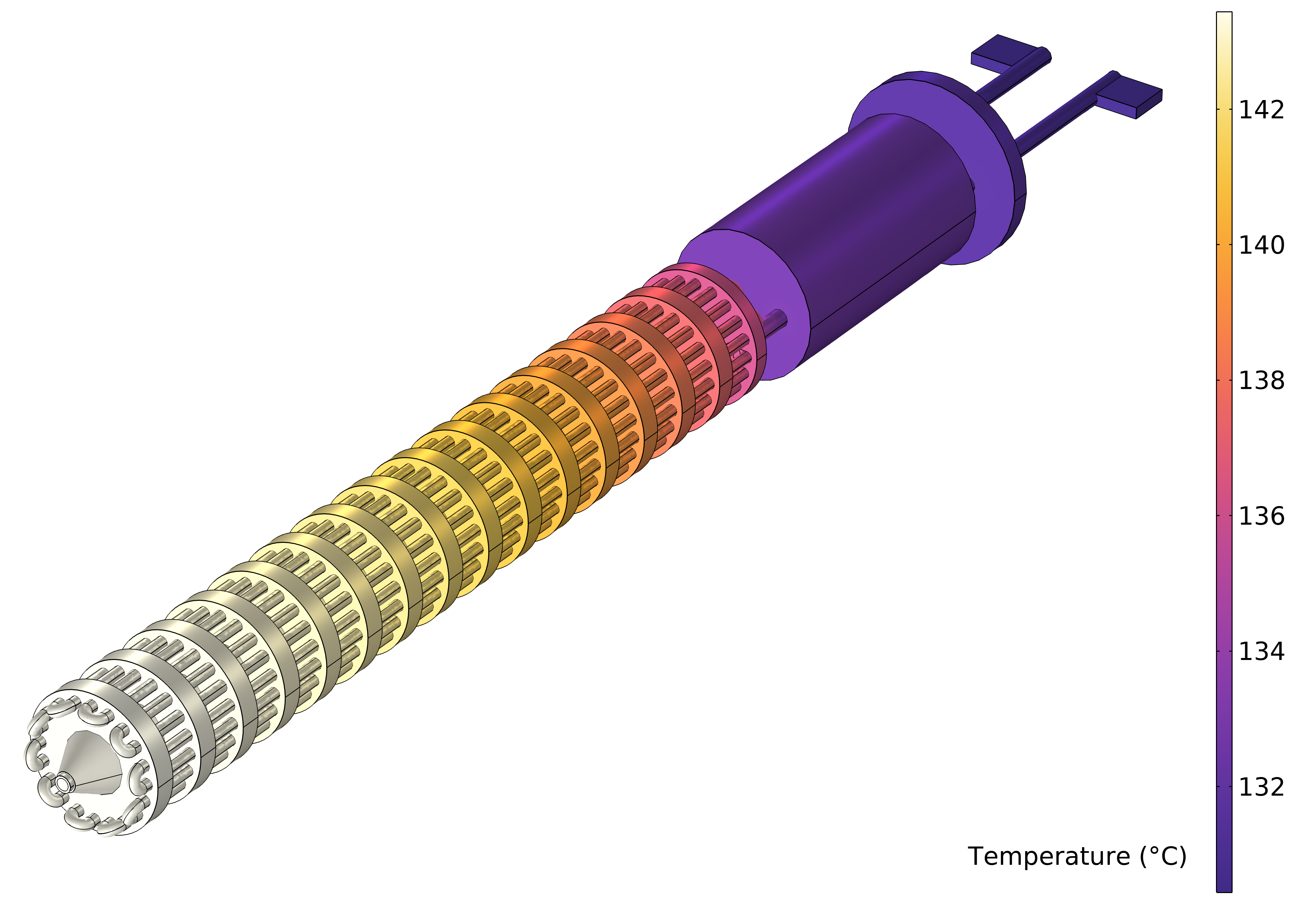

Resistive heating, also known as Joule heating, occurs when an electric current passes through a conductive material, generating heat due to the material's electrical resistance. While resistive heaters are simple in principle, their behavior can be highly nonlinear, influenced by temperature-dependent material properties, structural deformation, and thermal expansion.

Veryst offers expert modeling and simulation of resistive heating systems, optimizing electromagnetic, thermal, and structural performance. Our work includes:

- Designing and optimizing heating elements such as calrods, busbars, and cartridge heaters

- Analyzing material behavior under extreme temperatures

- Addressing mechanical stress induced by thermal expansion.

Induction Heating

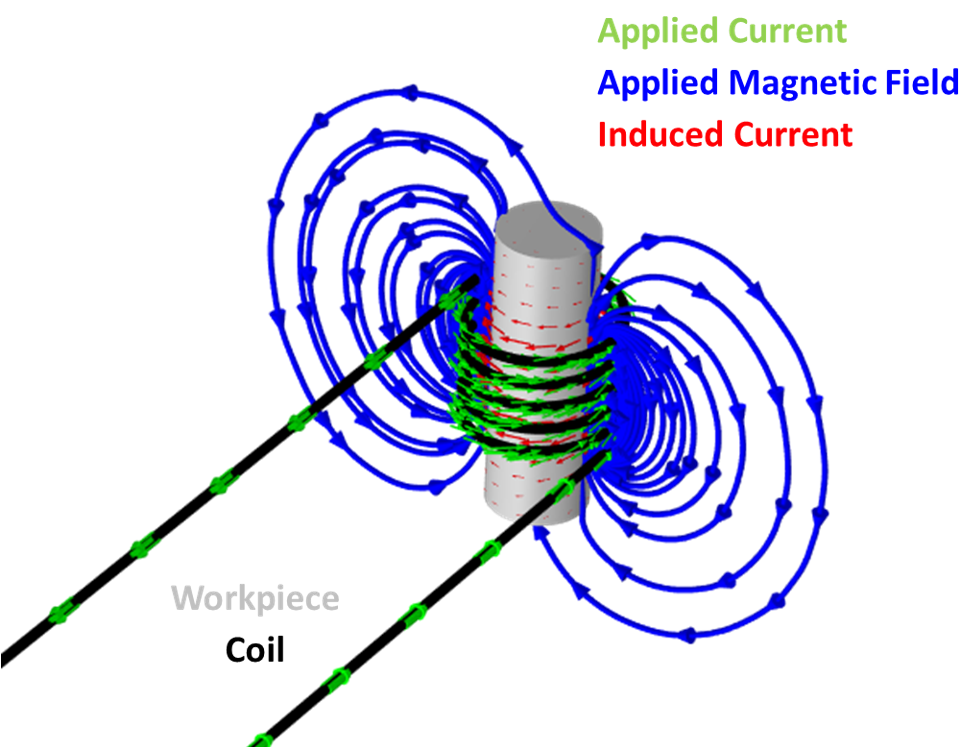

Induction heating is a highly efficient method for non-contact heating of conductive materials. A time-varying magnetic field induces eddy currents within the material, generating heat due to electrical resistance. This process is fast, precise, and energy-efficient, making it ideal for industrial and medical applications.

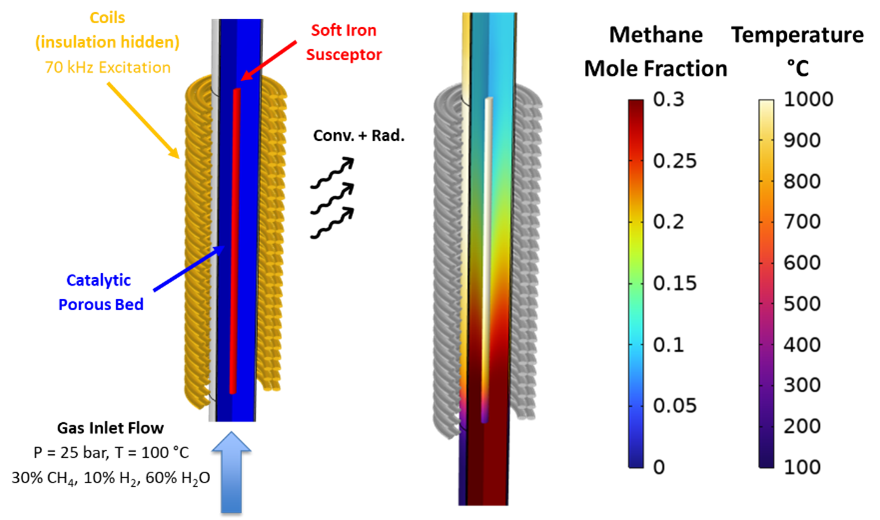

Veryst Engineering has extensive experience designing and optimizing coils to maximize heating efficiency, thermal management strategies for optimal process performance, and multiphysics simulation to incorporate coupled electromagnetic, thermal, fluid flow, and structural physics.

Example Applications:

- Inductively heated catalytic processes for chemical and energy applications

- Selective hardening of metal components in automotive and aerospace industries

- Eddy-thermography simulation for development of non-destructive testing techniques for aerospace parts.

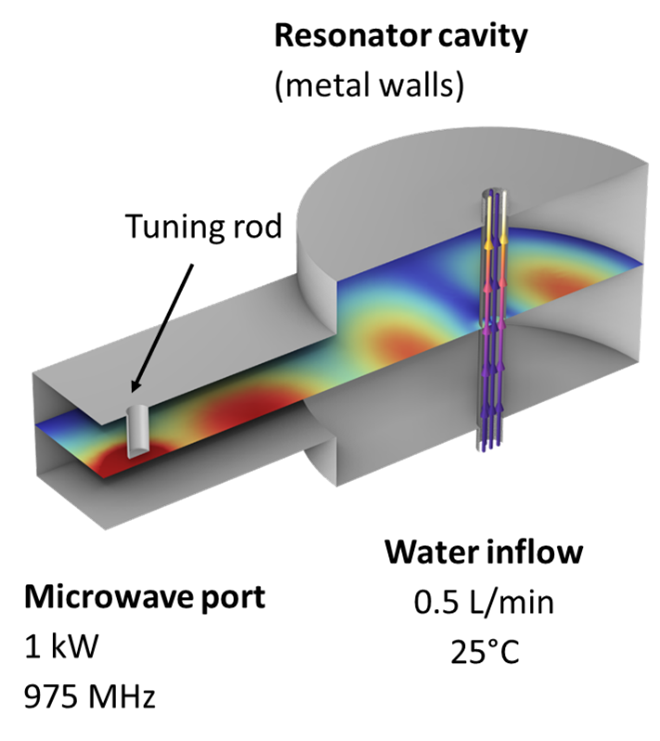

Dielectric (RF & Microwave) Heating

Dielectric heating (RF and Microwave) excites dipolar molecules such as water, polymers, or biological tissues using radio frequency (RF) or microwave energy, leading to rapid and uniform heating. This method is widely used in industrial, medical, and food processing applications.

Veryst Engineering has broad experience in:

- RF Ablation device modeling for medical applications

- Dielectric heating optimization in process heating systems

- Microwave chamber design for uniform energy distribution.

Why Choose Veryst Engineering?

- Multidisciplinary, Specialized Expertise: Our team of subject matter experts in electromagnetics, heat transfer, fluid mechanics, chemical reactions, and material science work closely to solve the most challenging problems in electrothermal system design.

- Close Partnership: We embed ourselves with your team to best understand design and commercial requirements so that we can offer holistic recommendations and superior outcomes.

- Actionable Insights: We tailor our approach to provide actionable and reliable design recommendations based on an established understanding of our client's objectives.

Veryst has extensive experience in designing and developing electromagnetic heating systems, leveraging deep expertise in electromagnetics, heat transfer, and computational modeling. We provide practical recommendations to help clients design more efficient and effective thermal systems across various industries.

Our engineers specialize in modeling and designing high-temperature electrical pass-throughs for CVD reactors, inductively heated catalytic processes, and RF tissue ablation devices. We also incorporate fluid flow, chemical reactions, and material selection into our analysis to optimize system performance.

To discuss your electromagnetic heating application with our team of experts, email us at contact@veryst.com today!

Joule (Resistive) Heating

Resistive heating, also known as Joule heating, occurs when an electric current passes through a conductive material, generating heat due to the material's electrical resistance. While resistive heaters are simple in principle, their behavior can be highly nonlinear, influenced by temperature-dependent material properties, structural deformation, and thermal expansion.

Veryst offers expert modeling and simulation of resistive heating systems, optimizing electromagnetic, thermal, and structural performance. Our work includes:

- Designing and optimizing heating elements such as calrods, busbars, and cartridge heaters

- Analyzing material behavior under extreme temperatures

- Addressing mechanical stress induced by thermal expansion.

Induction Heating

Induction heating is a highly efficient method for non-contact heating of conductive materials. A time-varying magnetic field induces eddy currents within the material, generating heat due to electrical resistance. This process is fast, precise, and energy-efficient, making it ideal for industrial and medical applications.

Veryst Engineering has extensive experience designing and optimizing coils to maximize heating efficiency, thermal management strategies for optimal process performance, and multiphysics simulation to incorporate coupled electromagnetic, thermal, fluid flow, and structural physics.

Example Applications:

- Inductively heated catalytic processes for chemical and energy applications

- Selective hardening of metal components in automotive and aerospace industries

- Eddy-thermography simulation for development of non-destructive testing techniques for aerospace parts.

Dielectric (RF & Microwave) Heating

Dielectric heating (RF and Microwave) excites dipolar molecules such as water, polymers, or biological tissues using radio frequency (RF) or microwave energy, leading to rapid and uniform heating. This method is widely used in industrial, medical, and food processing applications.

Veryst Engineering has broad experience in:

- RF Ablation device modeling for medical applications

- Dielectric heating optimization in process heating systems

- Microwave chamber design for uniform energy distribution.

Why Choose Veryst Engineering?

- Multidisciplinary, Specialized Expertise: Our team of subject matter experts in electromagnetics, heat transfer, fluid mechanics, chemical reactions, and material science work closely to solve the most challenging problems in electrothermal system design.

- Close Partnership: We embed ourselves with your team to best understand design and commercial requirements so that we can offer holistic recommendations and superior outcomes.

- Actionable Insights: We tailor our approach to provide actionable and reliable design recommendations based on an established understanding of our client's objectives.