Technical Challenge

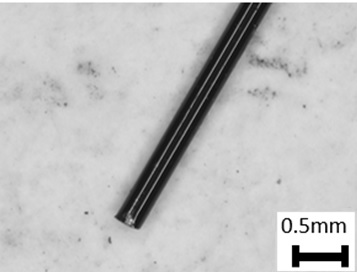

Shape memory alloys, like nickel titanium alloy (nitinol), are common in medical device applications. Nitinol is often used in fine wire form (Figure 1) in stents, catheters, or other braided materials.

Accurate simulations of such devices to predict and improve product performance require advanced test data collected at different temperatures. However, given the small diameter of these wires, performing standardized testing can be particularly challenging.

Veryst Solution

Veryst has developed a reliable method to test nitinol wires in uniaxial tension with an electromechanical test frame with knurled grips, a temperature chamber, and digital image correlation (DIC), shown in Figure 2.

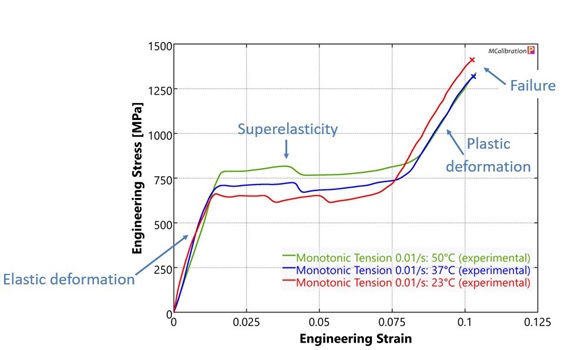

In this case, the nitinol wires were tested at three different temperatures, 23°C, 37°C, and 50°C, to capture the temperature-dependent response of the material. With this method, we examined the resulting stress-strain curves (Figure 3) that accurately capture the elastic deformation, the superelastic region, the plastic deformation, and eventual failure of the nitinol wires.

From the stress-strain curves, we determined that the nitinol wires have no change in elastic modulus between the selected temperatures, but as test temperature increased, there was a significant increase in the plateau stress in the superelastic region.

Veryst can test small diameter wires, including nitinol, in uniaxial tension at different temperatures. The resulting engineering stress-strain curves can then be used to calibrate a material model for use in finite element (FE) simulations.